Streamlining supply chain operations with Neal’s Supply Chain Optimization solutions

Supply chain optimization refers to the process of improving the operations of each step of a suppliers-to-customers supply chain. Its goal is to concurrently maintain or improve margins and customer satisfaction. Supply chain effectiveness is directly impacted by an ever-changing business environment due to fluctuations in the usual business conditions, black swan events (pandemic, war, unexpected inflation spikes, etc.), and quickly evolving consumer tastes and expectations. This make selecting the best approach for each step of the supply chain both challenging and time sensitive.

In this article, I will show how organizations can use sophisticated analytical tools and machine learning algorithms to improve their supply chain operations by:

- Reducing surplus inventory

- Cutting down production, distribution, and transportation costs

- Decreasing lead times

- Improving customer service

- Reducing time to act on issues and mitigating risks

- Maintaining resiliency, agility, and predictability to overcome problems with changing demands

To understand how analytics and machine learning can help with these challenges, however, one must be familiar with the components that make up the supply chain.

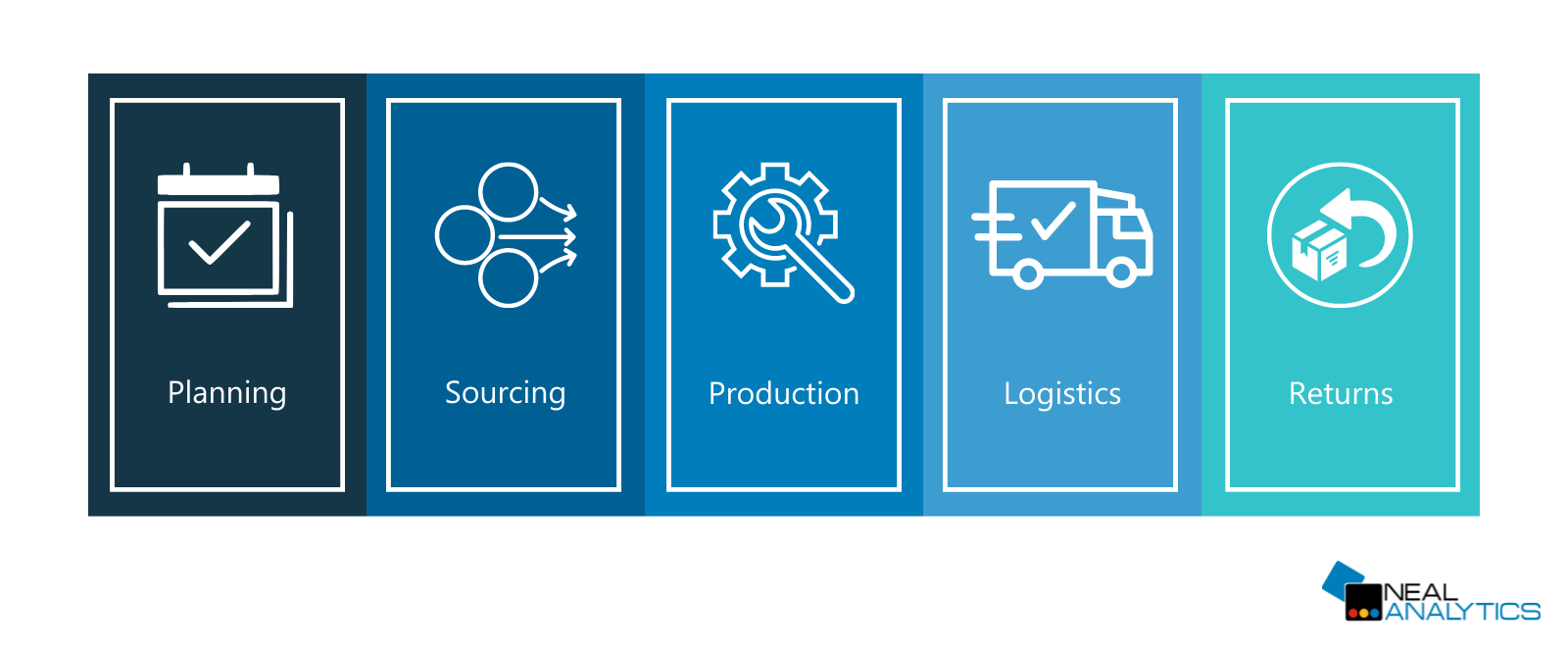

Key components of a supply chain

Staying on top of your supply chain management is important, but often challenging. A supply chain is a complex process that includes many interconnected operations, and it’s challenging to identify where the issue lies in the whole process.

Here, we consider the five basic components of supply chain management. Most of the issues will also fall under these categories.

1. Planning

Planning is a primary and key component of a supply chain which involves forecasting demands and planning materials and resources to meet that demand, along with production, distribution, sales, and marketing. The more historical data available to predict demands, the more accurate your forecasting will be. Along with the demand planning, this process also addresses supply planning, including safety stock planning, distribution planning, as well as supplier and customer collaboration.

Planning a supply chain can help streamline operations, cut operating costs, avoid delays, and enhance efficiency. The right supply chain plan can help save costs associated with various processes like purchasing, inventory management, manufacturing, logistics, and transportation.

2. Sourcing

Sourcing in a supply chain involves identifying, assessing, and managing potential suppliers who offer the best price aligning with your business goals. A well-structured sourcing plays a vital role in maintaining a competitive advantage by reducing costs and lead times and providing quality goods and services. The key principle of sourcing is not just saving costs but also strengthening the relationship between buyers and suppliers.

Building a strategic sourcing plan can contribute to the overall business value in the long run. It includes analyzing the business needs and historical spending, collecting data, conducting market analysis to select from a pool of suppliers, measuring performance, and improving the process on a continual basis.

3. Production

The production process deals with converting raw materials into finished goods, starting from production planning, testing, packaging, and assembling the finished products. This process also involves establishing rules for performance measurement, analyzing production facilities conditions, and regulatory compliance.

The production process is highly dependent on other supply chain elements like market demand, sourcing, inventory, and labor resource. Customer satisfaction is the key principle of this process, where customer feedback could be a driving factor for manufacturers to optimize their operations.

4. Logistics

In the supply chain, the delivery component is referred to as logistics. Along with the product quality, the customers are influenced by the speed of your delivery. This process is quite complex as it consists of many small activities like accepting customer orders, scheduling orders, managing payment modes, dispatching orders, sending invoices, and receiving payments. Many organizations rely on third-party delivery partners to deliver products that need extra care and effort, ensuring zero damages and minimal losses during transit.

This component also involves transportation and warehousing, stock monitoring, trials, and warranties for a delivered product.

5. Returns

Customer returns include the customer-centric post-delivery support process associated with all kinds of returned products. It’s also known as reverse logistics. The most common causes of purchase returns are damaged or defective products, unmet expectations, delays, delivering wrong items, or incorrect fit. The returning process is often critical for businesses as it can potentially deteriorate your relationship with the customers.

On the other hand, products are also returned to suppliers by manufacturers. This includes low-quality, expired, defective, or excessive raw materials bought from the suppliers.

Key solutions to optimize your supply chains

Once you are able to identify the challenges, the components of your supply chain that they impact, and the external and internal factors impacting the challenges, the next move is to select a reliable solution that can help solve them. Neal Analytics’ supply chain optimization solutions target these key components and help optimize the overall supply chain by leveraging modern AI and machine learning best practices and frameworks. The team of experts at Neal Analytics aims to maximize the impact of positive factors while mitigating those that might be impairing the supply chain.

Here, we discuss some key solutions that can enable organizations to identify and act on time and cost-saving opportunities throughout each stage of their supply chain optimization journey.

1. Advanced demand forecasting

Supply chain operations targeted: Planning and sourcing

Enriching forecasting methods with AI can help organizations ensure they have enough supply on hand to satisfy customers’ demands, optimize inventories, and improve service levels. The advanced demand forecasting solution mainly focuses on the initial planning and sourcing components of the supply chain. This technique can define demand drivers that allow organizations to drill down and better understand different internal and external factors impacting the demographics and customer segments.

This solution helps drive sales by ensuring demand is met and reduces waste by avoiding overstocked facilities with lower demand. With accurate forecasts, organizations can also focus on analyzing the number of staff required on a sales floor to achieve optimal customer wait times and help reduce spending on resources or activities that aren’t adding value.

Our solution delivers the flexibility to adapt and strategize based on sudden or unexpected events. Learn how a major retailer reduced waste in freshly cooked goods by 33% with the advanced demand forecasting solution.

2. Supply chain inventory optimizations

Supply chain operations targeted: Planning, sourcing, and logistics

Supply chain inventory optimization solution accounts for the planning, sourcing, and logistics components of a supply chain. This solution helps in maintaining the right amount of inventory to meet demand, lowering logistics costs, and avoiding common inventory issues like stock-outs, overstocking, and return orders.

Many organizations are challenged with the costs associated with lost sales, manufacturing delays, lost revenues, and customer churn. The other issue is the uncertainty caused due to situations like the COVID-19 pandemic, natural disasters, trade disputes, etc.

The inventory optimization solution uses emerging technologies like machine learning, data analytics, cloud computing, and AI. Neal leverages technologies like Azure ML and Azure Databricks to help organizations develop efficient replenishment strategies by identifying the top-performing SKUs. Using Project Bonsai, AI agents can help optimize regional inventory replenishment to create more stable and predictable stocking levels, thereby avoiding lost sales.

3. Production planning

Supply chain operations targeted: Production

Production planning deals with allocating raw materials, labor, and workstations to fulfill the manufacturing orders on time. Manufacturers often face challenges due to changing forecasts, raw material costs, logistics inefficiencies, and labor constraints. A poor production plan can affect a company’s top and bottom lines both at the production and supply chain levels. This solution targets the production component of a supply chain and helps reduce production downtime and optimize lead time.

Neal leverages ML models designed to ingest demand forecasting data including data for labor costs, material costs, shipping costs, and others, to optimize production planning. Using a Deep Reinforcement Learning (DRL) based AI agent, it becomes possible to train and deploy a solution that adapts to changing production optimization goals, environmental changes, and production downtime parameters.

These AI agents can also help determine amounts of product SKUs to manufacture, the best manufacturing schedules, and meet fluctuating customer demands and inventory needs.

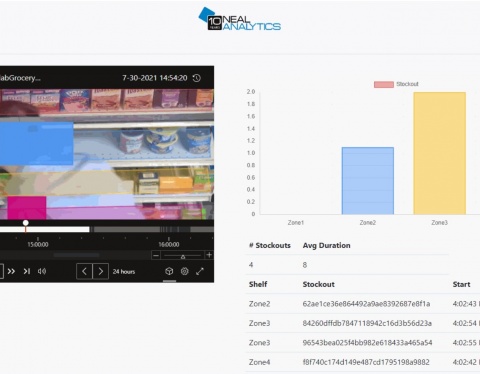

4. Warehouse storage and retrieval optimization

Supply chain operations targeted: Planning, logistics, and returns

Warehouses store a wide range of products that require different storage and handling strategies and make them easily available when needed. Poor warehouse layout, improper inventory management, lack of preparedness for seasonal demands, increased labor expenses, poor damage control, and inefficient retrieval decisions can lead to drastic financial impacts for an organization. As manual methods are static, it becomes difficult to adapt to the changing customer and market demands.

This solution considers various supply chain components like planning, logistics, and returns, and allows organizations to maintain the right inventory, optimize distribution networks, and reduce product damages. We build AI and ML models that work in conjunction with data from various IoT sensors, vision AI, labor work schedules and timecards, order invoices, and other relevant data that can significantly help warehouse managers optimize the operations. We leverage historical data to identify data and technology requirements and can help develop a roadmap for implementing warehouse storage and retrieval optimization solutions.

Our AI-powered supply chain optimization solution can help manufacturers improve both storage and retrieval operations by building an AI agent that can dynamically optimize and balance throughput and efficiency within the warehouse to maximize financial return.

5. Haulage strategy

Supply chain operations targeted: Logistics and returns

Modern haulage is under tremendous pressure struggling with factors like increasing demands, shortage of vehicles, rising fuel prices, unskilled or shortage of drivers, government regulations, and unpredictable environmental conditions.

To help mitigate these risks and improve performance and reliability, organizations need to enhance transparency and visibility across their haulage and use a well-planned haulage strategy. This solution focuses on the logistics and returns components, ensuring smooth and quick deliveries and customer satisfaction. With Project Bonsai, an AI agent can quickly and accurately determine the best actions for future haulage strategies based on historical data and business goals, helping them maximize throughput. Also, a well-executed haulage strategy can help maximize the life of assets and adapt to the changing conditions.

Learn how Neal helped a natural resource company optimize its haulage strategy with AI.

6. Spot price prediction

Supply chain operations targeted: Logistics

The spot price is usually the price quoted for shipping products from one place to another. These prices can go up and down depending on multiple factors like the type of shipping, fuel prices, routes, urgency and speed of shipping, and load-to-vehicle ratio. So, businesses lack control over the spot market rate at which they are quoted. The variability in spot prices can affect large businesses shipping their products internationally or over longer distances.

This solution mainly deals with the logistics component of a supply chain and ensures an organization saves on transportation costs. Neal has developed an ML model that predicts spot prices by identifying the key parameters and values impacting shipping prices, like shipping distances, speed, shipment size, locations, fuel prices, etc. These ML models use key parameter data to predict more accurate spot prices, which helps businesses to further negotiate spot bid prices to an optimal level to minimize costs and improve the performance management of their spot pricing team.

Conclusion

Supply chains are both complex and critical aspects of any business. Their dysfunctions or lack of end-to-end optimization will dramatically impact organizations’ operative effectiveness and, therefore, can impact on the bottom line and customer experience. By applying the latest proven ML and AI techniques across the value chain and leveraging the expertise of Neal Analytics organizations can optimize each step of their supply chain to improve their effectiveness, resilience, and agility in ever-changing business conditions.