Manufacturing

Transform your manufacturing with data, from production to delivery

Accelerating the transformation to Industry 4.0

At Neal Analytics, we help manufacturers plan, build, and deliver their products and services more effectively by leveraging the power of the cloud, IoT data from field assets and the shop floor, and AI.

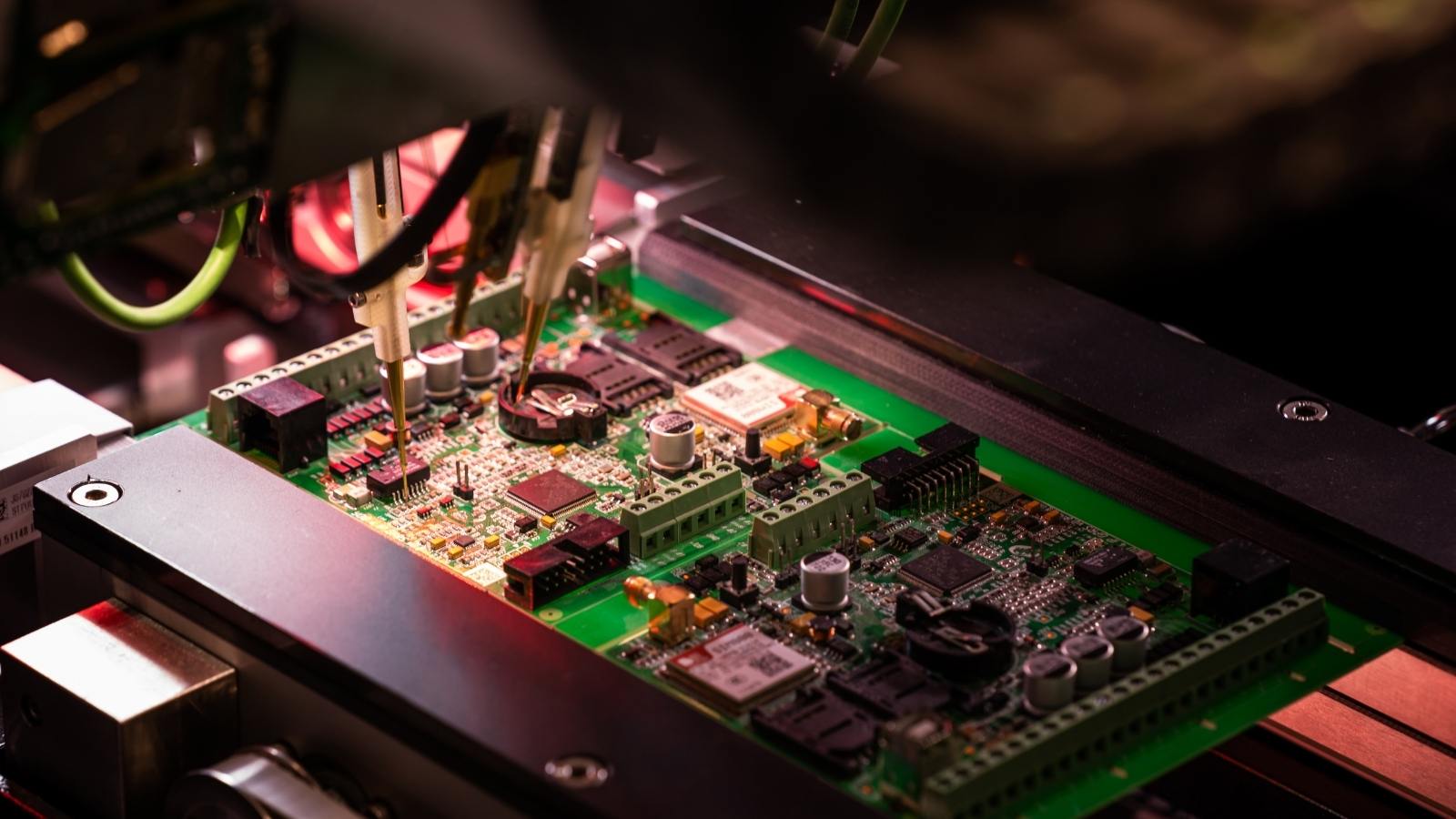

As equipment grows smarter, the data generated by these devices becomes a key driver for finding new productivity improvement opportunities. This (mostly IoT) data-driven transformation is one of the key components of what is commonly referred to as Industry 4.0.

To take full advantage of these new and rich data sets, manufacturers need first to modernize the underlying data platform. Then, through advanced ML/AI models, new opportunities emerge to improve the end-to-end manufacturing value chain, from planning to end-customer delivery.

Neal’s custom-built solutions leverage the latest cloud, data, and AI platforms and technology to prepare your organization for the future, solve your unique business challenges and delight your customers.

Intelligent manufacturing

We leverage our industry solution accelerators, cloud and data platforms expertise, and digital consulting services to help manufacturers accelerate their transformation journey to Industry 4.0 while minimizing risk and maximizing value.

Neal Analytics solutions are designed to support one, or several, of the following objectives:

Digitally empower your workforce

Generate insights from data to empower your workers

Operate safe and agile factories

Leverage AI to optimize your production lines for greater consistency, uptime and flexibility

> Predictive and prescriptive maintenance

> Production control systems optimization

> IoT analytics

Create more resilient supply chains

Optimize your supply chain by building the right products at the right time

Featured customer stories

Our solutions

Predictive and prescriptive maintenance

Many businesses struggle to get the most value out of their manufacturing equipment or field assets. Maintenance programs designed to keep equipment up and running are often reactive, leading to unnecessary downtime and lost productivity when a problem occurs.

New advanced analytics tools have the potential to shift the dynamic and enable maintenance programs to be proactive. These tools empower organizations to take action before a production line shutdown or field equipment failure. It reduces downtime and its financial impact and increases return on assets.

Prescriptive maintenance goes a step further by providing insights related to the root cause of an issue through automatic detection. It enables maintenance crews to plan spare parts usage and equipment requirements for repairs before visiting a site or customer. Prescriptive maintenance saves time and helps maintenance managers drive better outcomes.

Production control systems optimization

Improving complex industrial production processes can provide outsized returns. Often, a few percent of productivity increase can generate large bottom-line returns. However, because of their complexity and the risks & costs associated with halting or slowing down a production line, fine-tuning these process parameters often offers unacceptable risk/reward profiles.

Autonomous systems can help address this dilemma by leveraging AI to improve these processes.

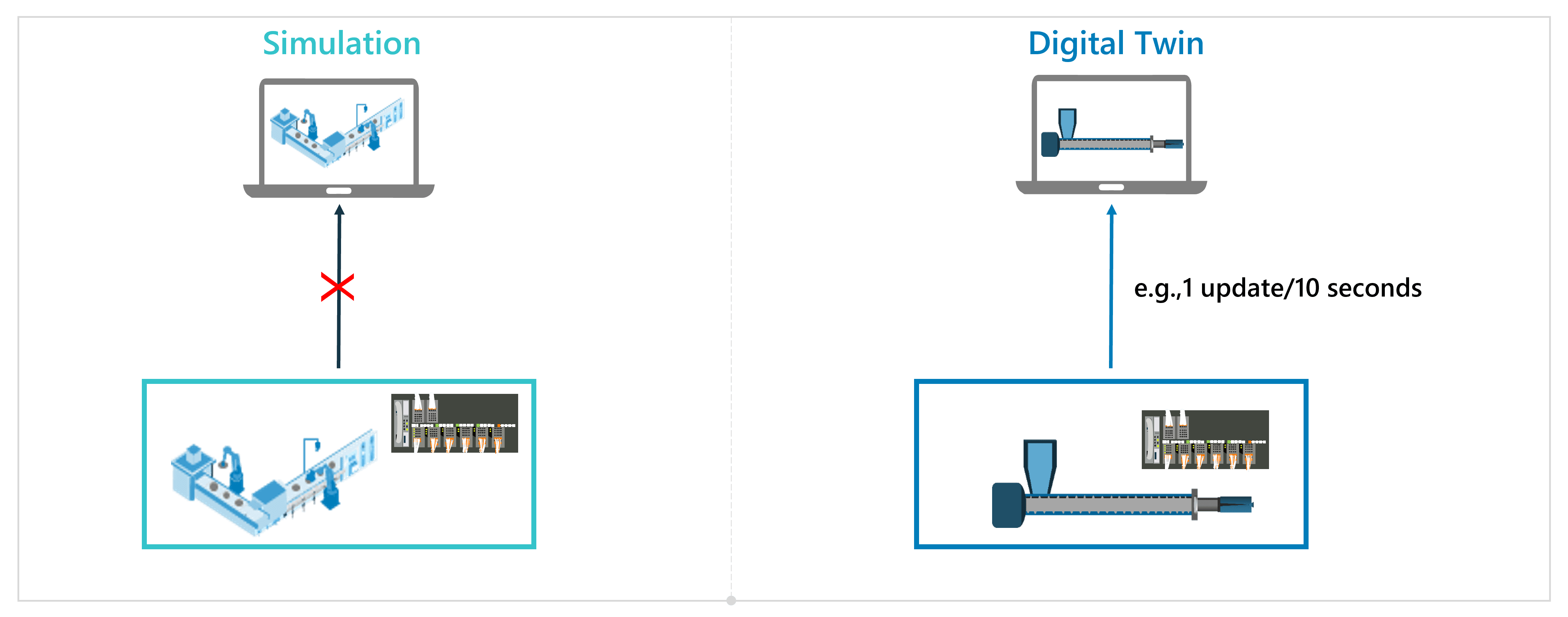

Autonomous systems combine simulation and Deep Reinforcement Learning (DRL) to achieve new levels in equipment performance. Rather than programmed rules, these systems self-learn through trial and error.

The first step to reinforcement learning is to build a reliable simulator. These simulators are designed to capture the intricacies of the environment. From there, an AI agent is used to learn the optimal path based on a value function.

Data visualization

Transform sensor data and equipment information into intuitive visuals for high-level insights across sites over time. Leverage our Power BI expertise and empower your team with custom dashboards that consolidate data into easy-to-navigate visual representations of production, transport, and distribution processes.

Advanced demand forecasting

Unsold inventory heavily impacts the balance sheet. Manufacturing delays impact customer satisfaction and sales.

By forecasting demand more accurately and gaining insight into which factors drive market demand, manufacturers can reduce both unsold inventory and delivery time.

Advanced demand forecasting from Neal Analytics helps provide a clear picture of where demand is heading, providing business decision-makers with the information they need to optimize operations and improve both top and bottom lines.

StockView for inventory

StockView from Neal Analytics leverages Microsoft’s Azure Stack Edge and the Azure platform to provide organizations the ability to automatically detect when store shelves or stockrooms run out of items, enabling employees to restock them rapidly.

IoT analytics

Sensors have the potential to provide clarity and visibility into the operations of a manufacturing organization. However, to create value, sensor data must be connected and analyzed with the proper context. It requires infrastructure planning, execution expertise, and advanced analytics know-how.

Process automation

Scale your operations by automating inefficient, manual processes, and maximizing your workforce. Leverage bot or low code/no-code solutions such as Power Automate to automate processes using new or existing AI and ML solutions such as predictive maintenance.

Digital twins

Digital Twins are virtual representations of a real-life system. They leverage IoT technologies and cloud models to provide a digital representation of a real-world system. Digital Twins can start from simple system states representations to full simulations that can then be used for use cases such as operator training, in depth analysis without disturbing an existing process, what-if analysis/forecasting, and deep reinforcement learning training. They can model simple single-device “things,” but also full manufacturing lines, factories or more. Azure Digital Twins . To learn more about what separates a simulator from a digital twin please refer to this blog